Rollerbed Steamer

For highspeed continuous pretreatment.

Features

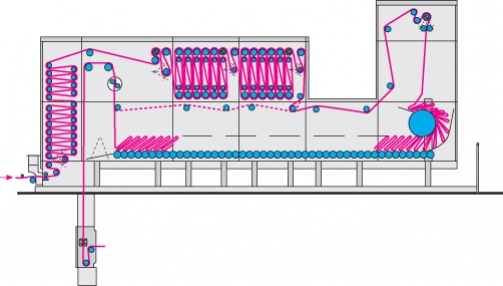

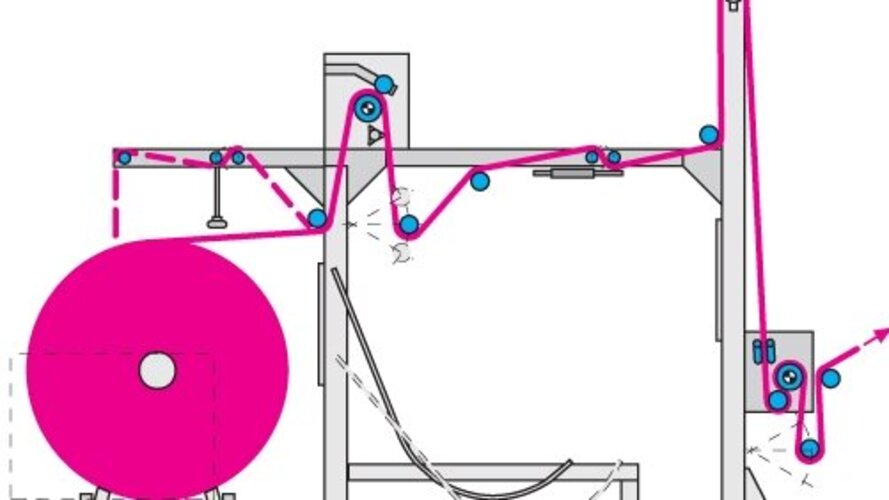

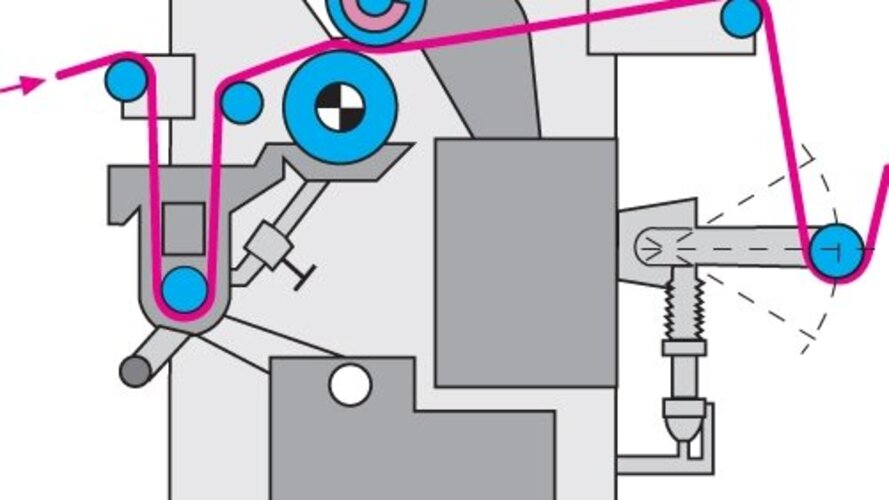

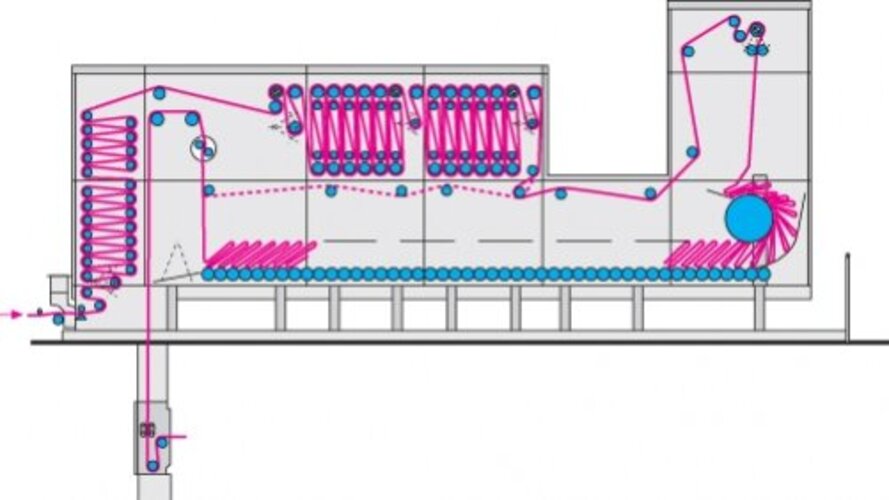

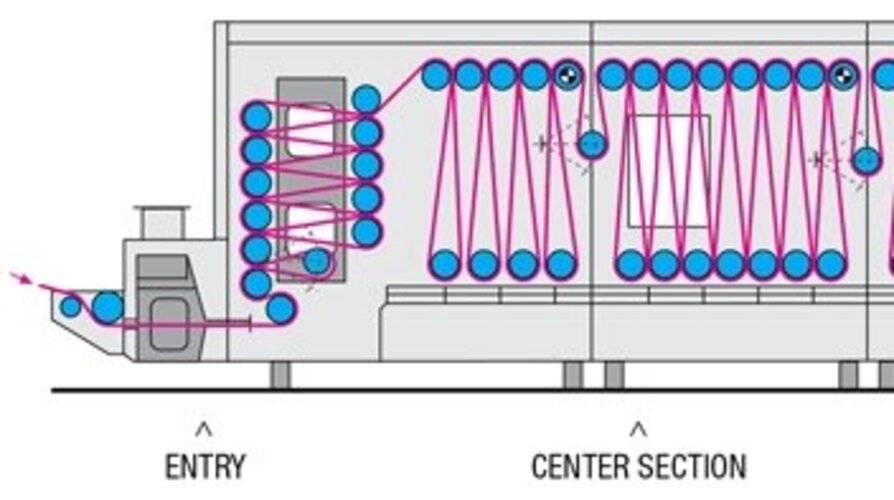

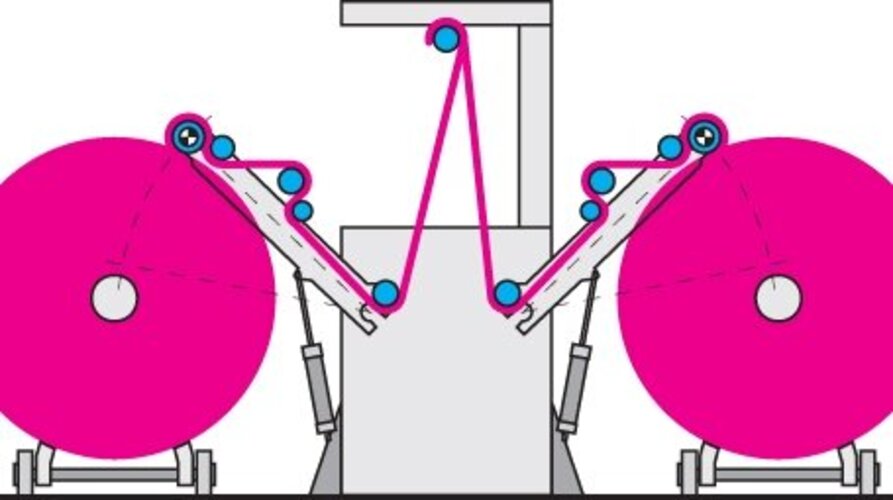

- Entry section with heated lip seal and horizontal fabric path for even liquor distribution

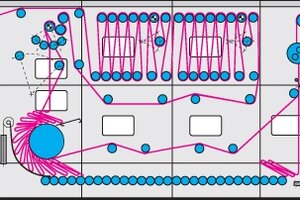

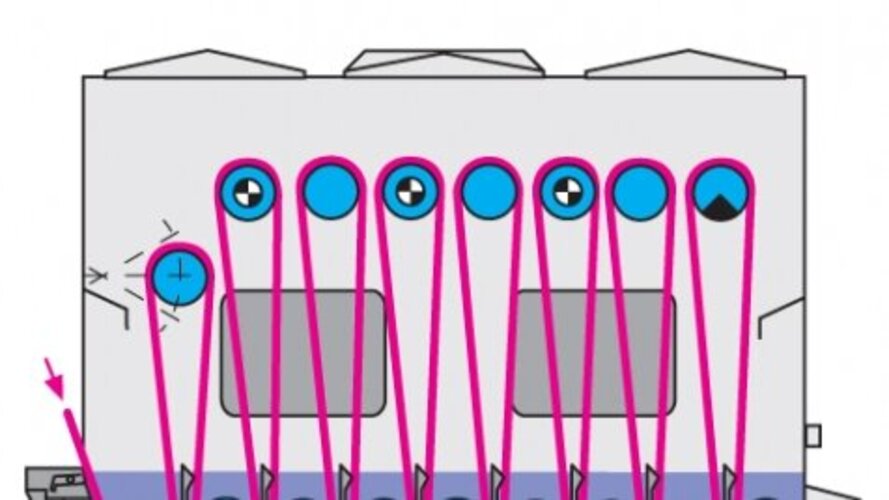

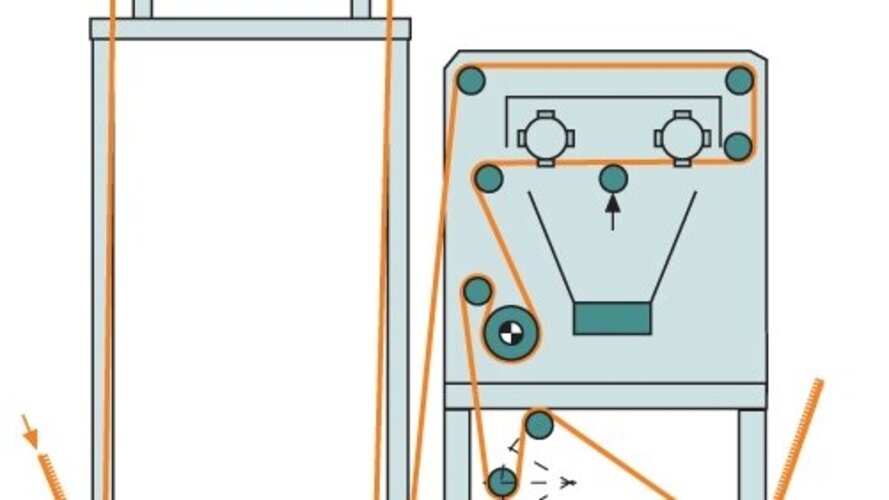

- Central sections with tightstrand vertical fabric path

- Dwelling section with pulling device, plaiter and reversing drum for plaiting on the rollerbed

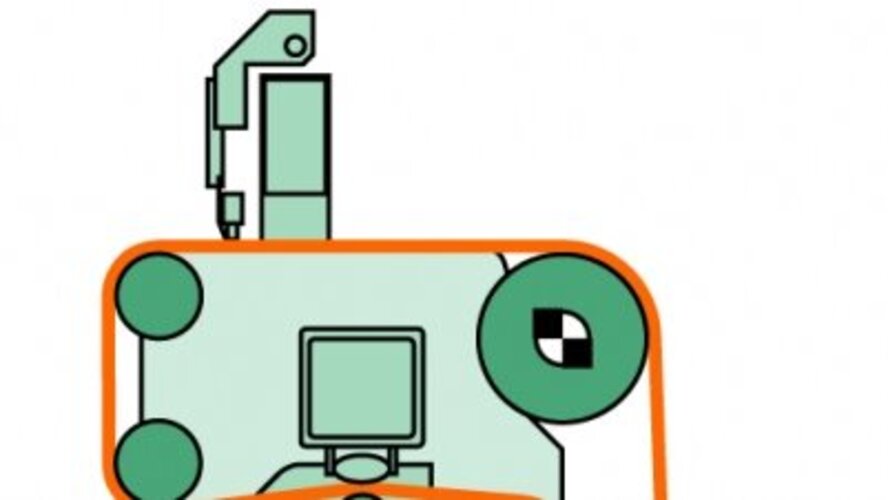

- Exit section with sensing blade, cloth tensioner and expanding unit

- Spray nozzles for cleaning

- Roof heating and rollerbed by-pass optional

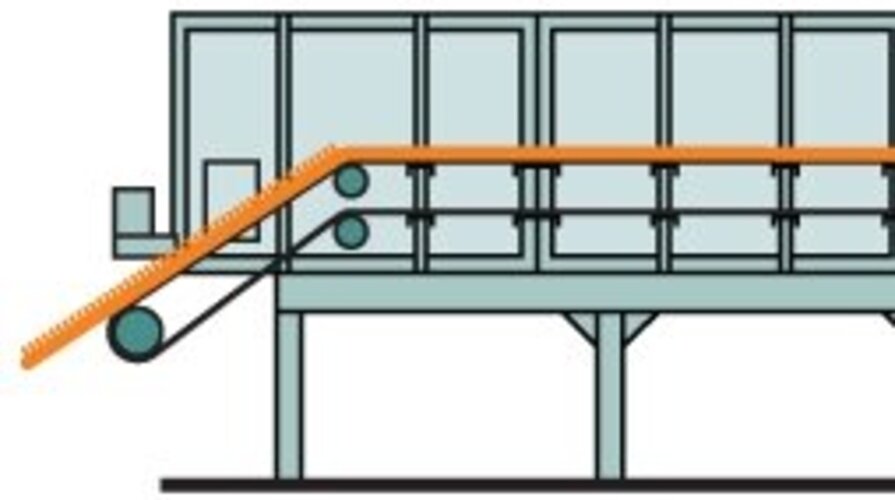

- Housing in self-supporting segment construction in ground-level or elevated execution with direct steam feeding

- Take up of the plaited fabric at the outlet is always from the top, thus giving low tension, distortion-free fabric guiding

Technical Specs

- Working Width: 900-3400 mm

- Fabric Content:

- Inlet Section: 22,8/21,0

- Center Section: 18,0 single feeding in; 27,5 double feeding in

- Fabric Feeding on the Rollerbed: max. 50 kg/m2