Clarification

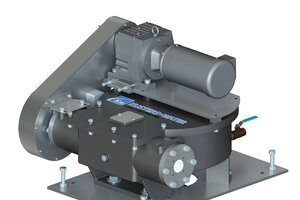

Cast Iron Bridge Supported Drives

All Kusters Water clarifier and thickener drives are designed in accordance with the latest AGMA (American Gear Manufacturers Association) standards to ensure the absolute highest quality. Assembly and inspection of every unit is performed at Kusters Water’s Power Division production facility prior to shipment.

Centrifugally cast bronze or ductile iron worm gear drives enclosed in ASTM A-48 cast iron housings offer superior corrosion resistance and exceptionally long service lives. Worm gear units are offered in many standard sizes up to 30″ main gear pitch diameter. Commonly used in municipal, industrial and mining clarifier and thickener applications.

- Ductile Iron or Bronze Main Gears

- Corrosion Resistant Cast Iron Housings

- Replaceable Strip Liners (some models)

- Replaceable Ball Bearings (some models)

- Condensation Removal System

- Easy Maintenance

- Robust Design

- Can be rebuilt to factory new tolerances in the field

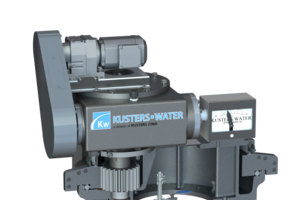

Cast Iron Pier Supported Turntables Drives

All Kusters Water clarifier and thickener drives are designed in accordance with the latest AGMA (American Gear Manufacturers Association) standards to ensure the absolute highest quality. Assembly and inspection of every unit is performed at Kusters Water’s Power Division production facility prior to shipment.

Internal tooth spur gear drives fully enclosed in ASTM Class 40 Cast Iron housings are offered in 5 standard sizes: 30″, 42″, 60″, 80″ and 100″ main gear pitch diameters. For use in municipal, industrial and mining clarifiers and thickeners. Every unit can be equipped with worm, helical, planetary or cycloidal gear reducers.

- Split Main Gear Design

- Corrosion Resistant Cast Iron Housings

- Replaceable Strip Liners

- Replaceable Ball Bearings

- Exceptionally Deep Oil Reservoirs

- Condensation Removal System

- Ductile Iron or Cast Steel Main Gears

- Can be rebuilt to factory new tolerances in the field

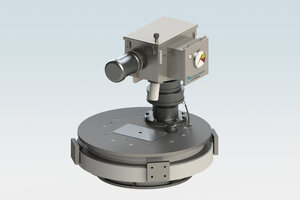

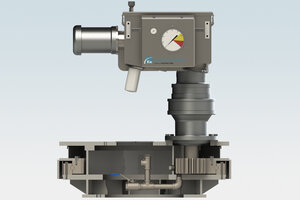

Hydraulic Clarifier Drives

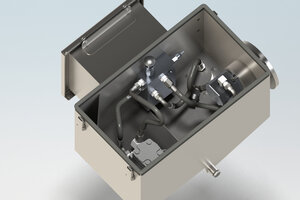

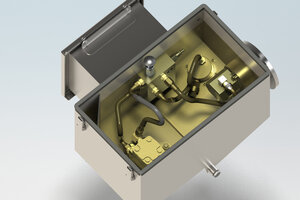

Hydraulic Powered Bridge Supported Drive Units (Type-H)

Technically advanced hydraulic powered Type H drives are available in a wide range of operating torques and output speeds. Power is introduced through a standard “C-Face” mounted motor connected to a low speed, high torque hydraulic power system with integral valves, pump, hydraulic motor, filter and appurtenances fully enclosed in a 304 Stainless Steel housing / oil reservoir.

All Kusters Water clarifier and thickener drives are designed in accordance with the latest AGMA and / or ISO standards to ensure the absolute highest quality. Assembly and inspection of every unit is performed at Kusters facility prior to shipment.

Overload Protection

Precise torque monitoring is a major advantage of the Type H drive system. The overload system includes alarm and motor cut-off switches that are activated by an increase in operating pressure in the hydraulic system that is directly proportionate to the torque load on the rotating mechanism. Each unit includes a maximum torque pressure relief valve which takes the place of the less accurate mechanical shear pins and allows the unit to gradually stall without damage to the rotating mechanism. Torque is monitored with a liquid filled gauge that reads in actual operating torque (Ft-lbs) or (N-m).

- Gauge Readings in Actual (Ft-lbs) or (N-m)

- 304 Stainless Steel Housings

- External Oil Filter with Replacement Gauge

- Accurate Glycerin Filled Torque Gauge

- Max Torque Pressure Relief Valve

- Directional Valve

- 4-20mA Output for Remote Monitoring

- Increased Protection to Clarifier Mechanism

- Eliminate chains and sprockets

- Eliminate shear pins

- Low Maintenance

- New or Retrofits

- Painted Steel

- 304 or 316 Stainless Steel

- Hot Dip Galvanized Steel

- Specialty Stainless Materials

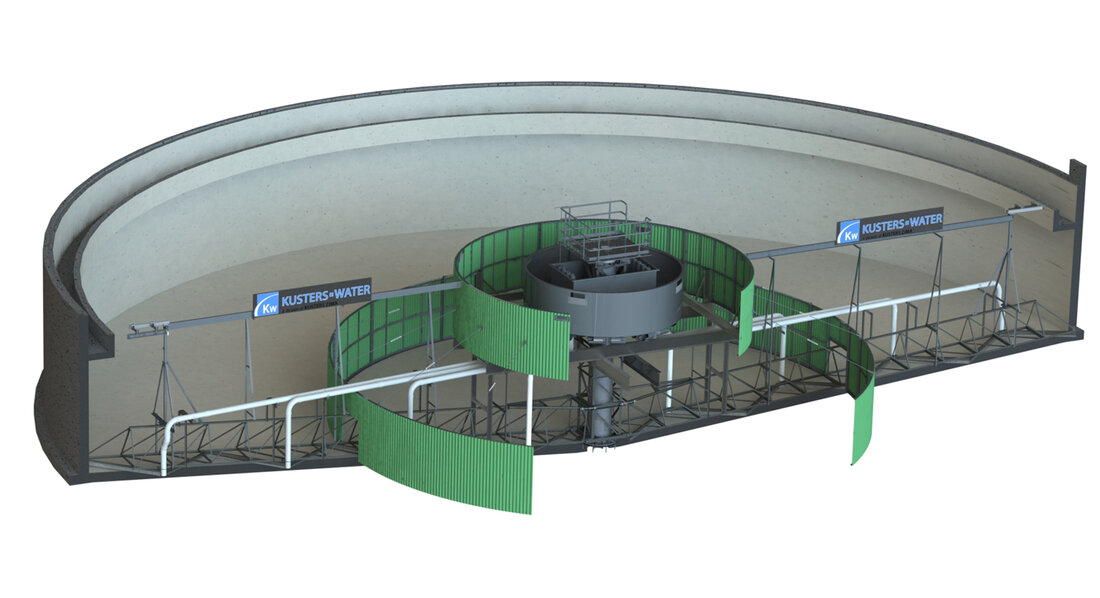

Flocculating Clarifiers

Kusters Water flocculation clarifiers are particularly effective for flocculation and clarification of municipal and industrial water supplies, screened primary sewage, wastes with high grit content, and industrial wastewater containing heavy settleable solids. Units can also be adapted to Tertiary waste treatment as well as potable coagulation.

Individual flocculators, or dual concentric turntable style flocculators are available. Properly sized paddle area and accurately computed energy gradients ensure optimum performance.

- Simple Operation

- Low Maintenance

- Independent Mixer Design

- Low Shear Flocculation

- Feedwell Baffles for Improved Flocculation

- New or Retrofits

- Painted Steel

- 304 or 316 Stainless Steel

- Hot Dip Galvanized Steel

- Specialty Stainless Materials

LA-EDI Clarifier Inlets

The Los Angeles Energy Dissipating Inlet, (aka. LA-EDI) was developed to address short circuiting issues common within the clarifier center well. The patented inlet design promotes flow impingement, enhances flocculation and minimizes short circuiting; the net result is the ability to handle higher flow rates through the clarifier basin. For more than 15 years, Kusters Water has been providing customers around the world with superior clarifier designs utilizing LA-EDI inlets. LA-EDI designs are offered in two configurations. Type I –Separate LA-EDI well, located within a feedwell. Typically installed on larger clarifiers >60ft. Type II– Integral LA-EDI, which incorporates the feedwell baffles into one well. Typically installed on smaller clarifiers < 60ft.

- Enhances flocculation of activated sludge particles

- Improves formation of flocs when using polymers

- Eliminates the “rat-holing” due to turbulence in area below the centerwell

- Optimizes the separation and settling of suspended solids particles

- Minimizes the carry-over or solids ordinarily transported by density currents

- Enhances the uniform formation of sludge blanket

- Increases treatment capacity over conventional “scooped” or “gated” EDI’s

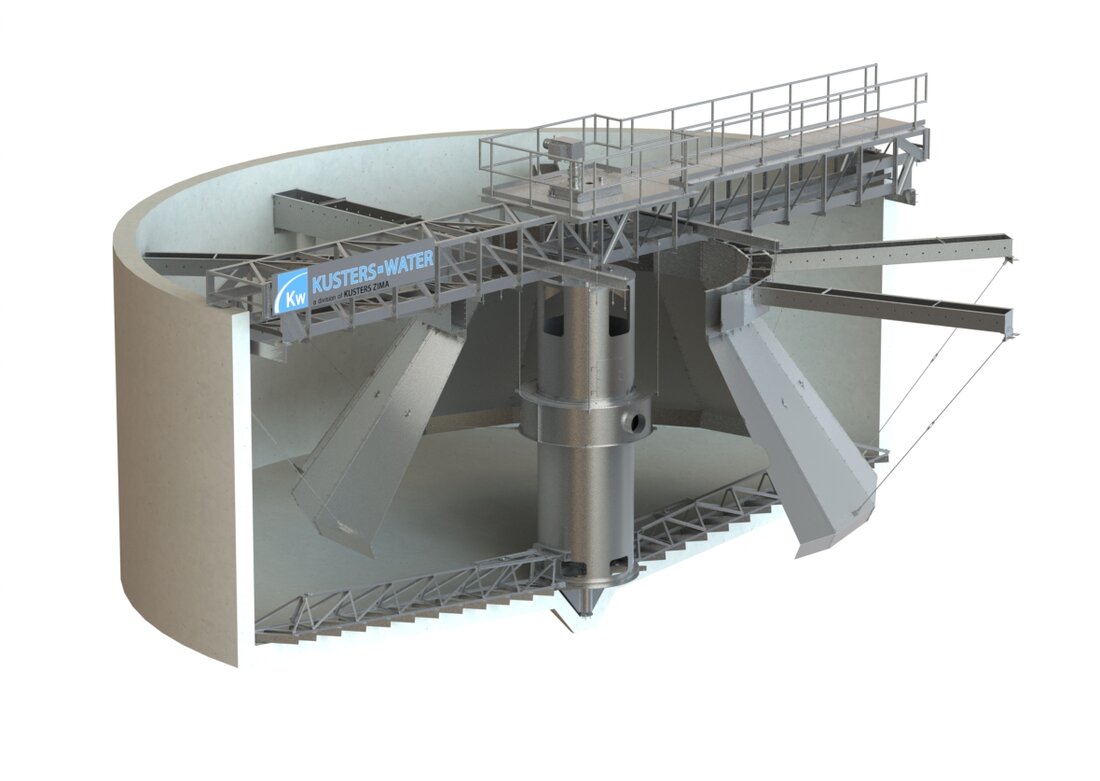

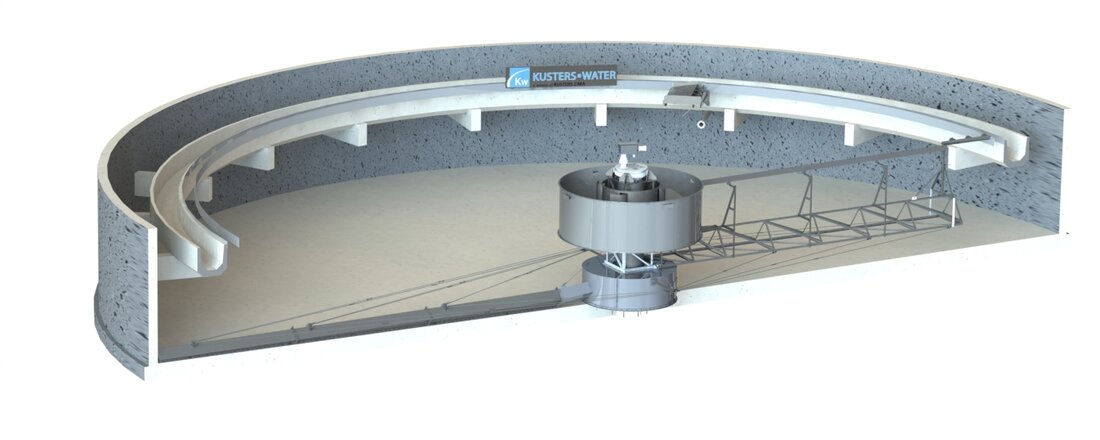

Solids Contact Clarifiers

Kusters Water’s units employ proven recycle solids contact principal for highly efficient flocculation, sedimentation, and clarification in a single compact basin. Solids contact units are widely used for the removal of turbidity for lime softening, and for chemical coagulation in municipal and industrial applications.

The slow speed, large diameter impeller recirculates large quantities of fresh precipitate through the recirculation drum, achieving superior solids and complete chemical reaction. The formulation of settleable floc particles occurs in the large, slow mixing reaction cone. An automatic sludge discharge system maintains an optimal solids volume along the clarifier bottom for efficient solids contact within the mixing zone.

The throughput follows a spiraling downward path to the outlet under the edge of the skirt. That is followed by circumferential, vertical rise clarification – Free of density currents and short circuiting, making possible an unusually clear overflow and dense underflow in an easily controlled, hydraulically and chemically stable system. As the flow passes upward, the decreasing upflow velocities of the floc particles cause dynamic separation of the solids from the treated water.

Radial launders provide uniform effluent discharge while maintaining the upflow pattern. The radial launders are available with v-notches or submerged orifices.

- Central Draft Tube, Side or Bottom Feed

- Low Shear Recycle Mixer Design

- High Efficiency, Low HP Recycle Mixer

- Variable Speed Mixer for Optimized Performance

- Stainless Steel Impeller and Shaft

- Axial Flow Mixer (Improves Recycle, uses less power)

- Independent Mixer and Rake Drive

- New or Retrofits

- Painted Steel

- 304 or 316 Stainless Steel

- Hot Dip Galvanized Steel

- Specialty Stainless Materials

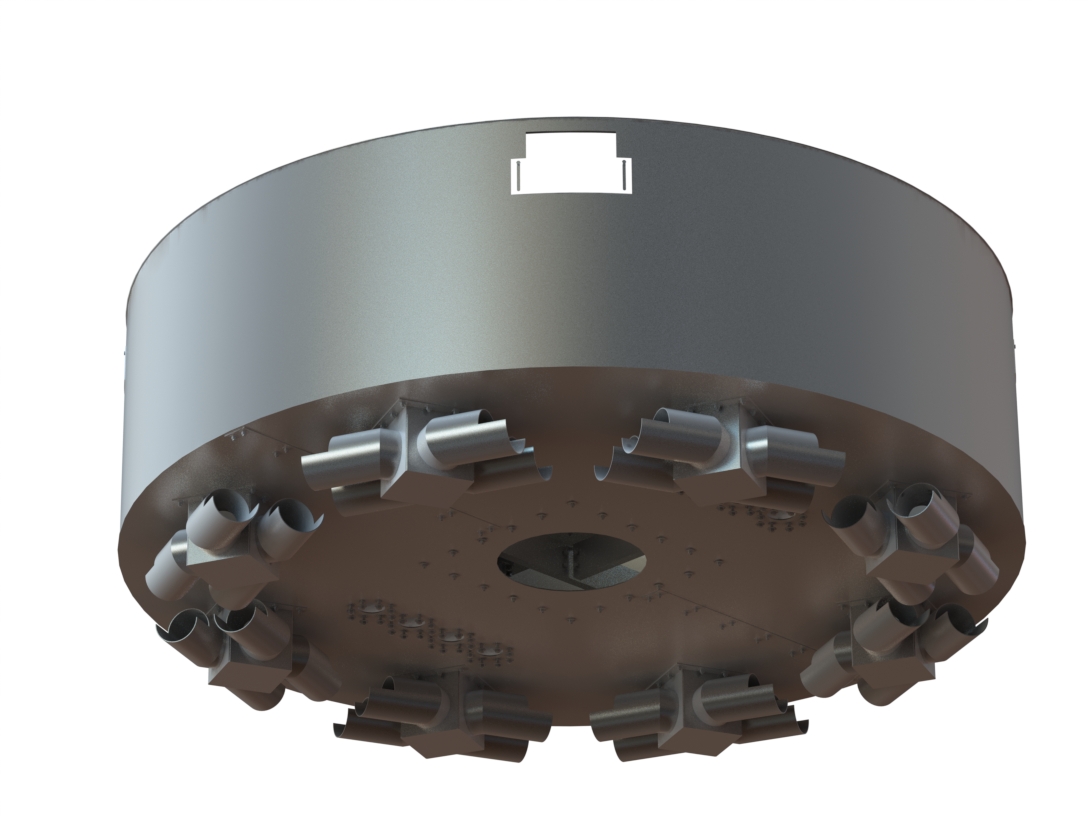

Spiral Blade Clarifiers

Kusters Water spiral blade clarifiers are commonly used in primary and secondary clarification. The logarithmic spiral curve and deep blades provide a more effective means of sludge transport. Variable rotational speeds are recommended to allow for optimizing sludge removal and overall clarifier performance.

Clarifiers are offered in sizes ranging from 20′ to 250′ ft diameter. Primary, Secondary and Final clarification are typical applications. Every unit includes a worm or spur gear drive unit designed in accordance with the current AGMA standards to ensure the absolute highest quality and a minimum 20 year service life.

- Rapid and Efficient Sludge Transport

- Deep Spiral Blades

- Higher Tip Speed (10-22 fpm)

- Single and Dual Blade Design

- Simple Operation

- Low Maintenance

- New or Retrofits

- Painted Steel

- 304 or 316 Stainless Steel

- Hot Dip Galvanized Steel

- Specialty Stainless Materials

Standard Scraper Clarifiers

Pier supported scraper clarifiers are designed for all applications involving sludge removal. Flow enters through the center pier then discharges through outlet ports located at the top of the center column into either a controlled energy inlet or feedwell. The energy inlet / feedwell dissipates the influent energy, minimizes density currents and enhances settling. Solids are collected at the bottom of the basin and raked to a collection sump located in the tank floor. The clarified effluent exits over the weir plates and out of the basin.

Clarifiers are offered in sizes ranging from 10′ to 250′ ft diameter. Primary, Secondary and Final clarification are typical applications. Every unit includes a worm or spur gear drive unit designed in accordance with the current AGMA standards to ensure the absolute highest quality and a minimum 20 year service life.

- Simple Operation

- Low Maintenance

- No Mechanical Seals

- Low Capital Costs

- New or Retrofits

- Painted Steel

- 304 or 316 Stainless Steel

- Hot Dip Galvanized Steel

- Specialty Stainless Materials

Suction Lift Clarifiers

Kusters Water rapid sludge removal clarifiers are specifically designed to provide quick and uniform removal of return activated sludge (RAS), Model HBSL collectors utilize collection pipes located at multiple points along each arm. Suction generated by a differential head developed from the partially submerged return sludge well located at the center of the clarifier. Each collection pipe is equipped with a return flow variator that controls the rate of sludge return and provides a visual indicator of the quality of RAS. Every pipe discharges into the rotating center return sludge well, then by gravity exits through a vertical steel pipe located inside the center pier. The size and quality of pipes are selected according to the RAS flow rates.

Vertical Tube, Suction Lift Clarifiers (HBSL-S)

Model HBSL-S, featuring vertical draft tubes and rotating sludge collection troughs simplify operations. The unique design of the vertical RAS pipes are less prone to clogging, easy to clean, provide better visibility of RAS flow, and improve surface scum collection via the rotating RAS trough, resulting in no scum pits required, no scum pumps, etc.

- Uniform sludge removal over entire basin

- Minimizes “rat-holing”

- Visual indication of RAS

- Individual control of each RAS line

- No scum skimmer or scum trough required (Model HBSL-S)

- New or Retrofits

- Optional Mid-Radius Baffle can be added

- Painted Steel

- 304 or 316 Stainless Steel

- Hot Dip Galvanized Steel

- Specialty Stainless Materials

Tapered Header Suction Clarifiers

Kusters Water rapid sludge removal clarifiers are specifically designed to provide quick and uniform removal of return activated sludge (RAS), each clarifier utilizes a rotating tapered sludge collection header and manifold assembly to remove activated sludge. Settled solids are collected through orifices located along the full length of the header. Varying orifice size and spacing are computer generated to provide the desired velocities throughout the entire assembly. Suction is typically provided by direct connection of the return activated sludge pumps to a central draw-off manifold at the tank bottom. An optional rake arm opposite the sludge header is available to collect any remaining solids. Sludge headers are offered in either single or dual configurations.

- Uniform sludge removal over entire basin

- Low profile sludge collection header, less likely to disturb sludge blanket

- Simple Operation

- Low Maintenance

- Minimizes “rat-holing”

- New or Retrofits

- Independently Tested and Verified Header Design.

- Painted Steel

- 304 or 316 Stainless Steel

- Hot Dip Galvanized Steel

- Specialty Stainless Materials

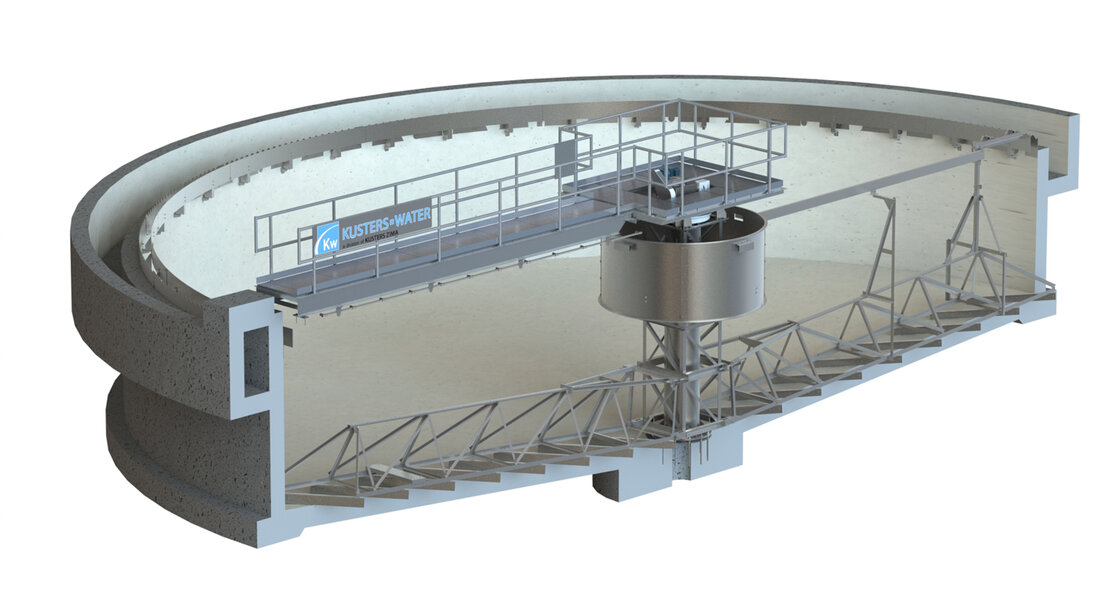

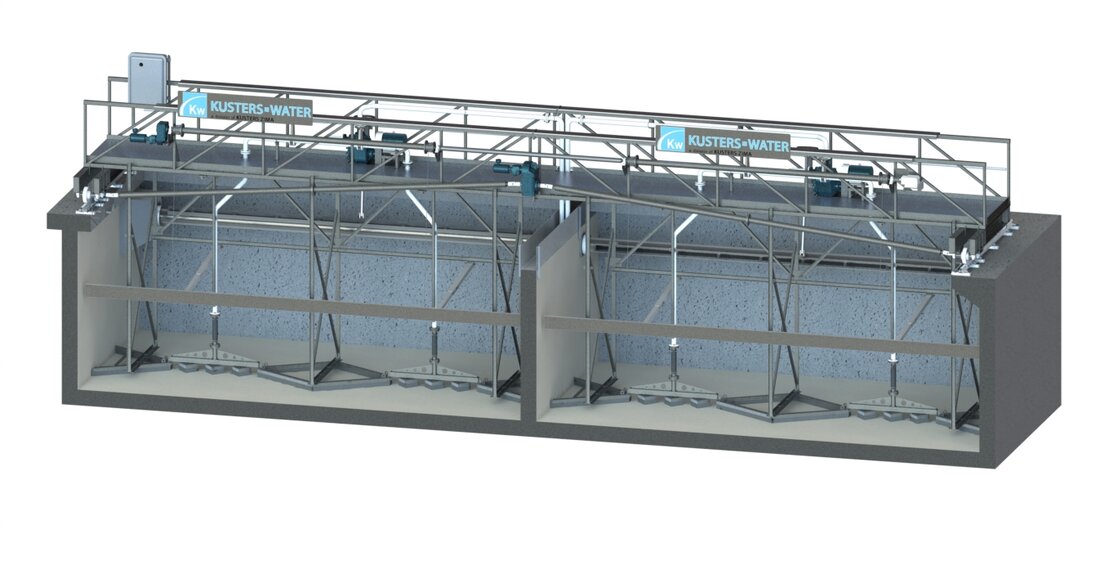

Traveling Bridge Clarifier

Kusters Water traveling bridge clarifiers are designed for installation in new or existing concrete basins for the removal of settled solids and floating material.

The sludge collector mechanism is supported from the traveling bridge and spans the width of the basin. Skimmers can be included for the collection and removal of scum. Power supply is provided in the form of a collector slip ring or festooning system. UL Listed Controls can be provided for a fully automated systems, requiring minimal operator attention.

Maintenance is simple, with the majority of service items located at the bridge level, above the liquid. Lower scrapers need only be inspected semi-annually. Materials of construction that can be offered include: Galvanized Steel, Painted Steel, 304 Stainless Steel or 316 Stainless Steel.

- Simple Operation

- Bridge Mounted Pumps

- Reliable Cog Wheel Drive

- New or Retrofits

- Cog wheel, or standard drives are available

- Painted Steel

- 304 or 316 Stainless Steel

- Hot Dip Galvanized Steel

- Specialty Stainless Materials