Vacuum Technology

The Superiority of EVAC System Modules

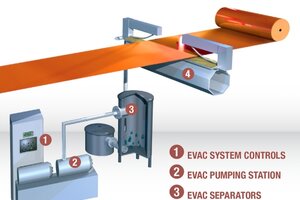

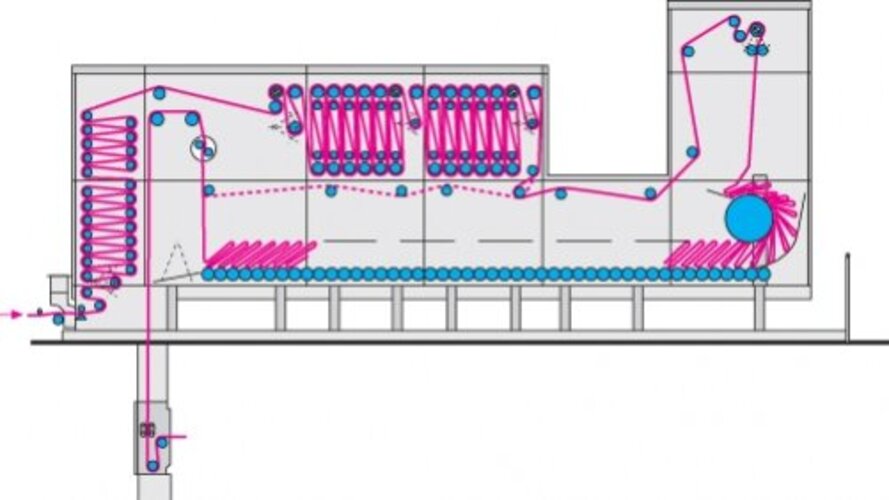

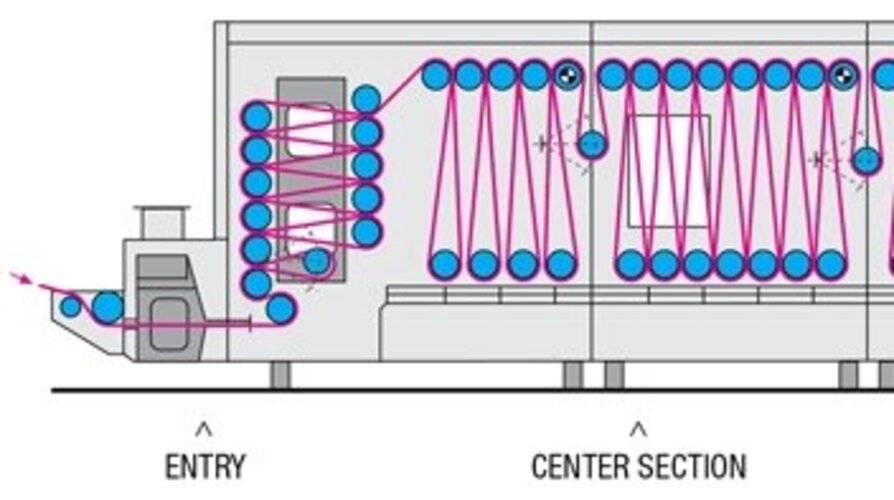

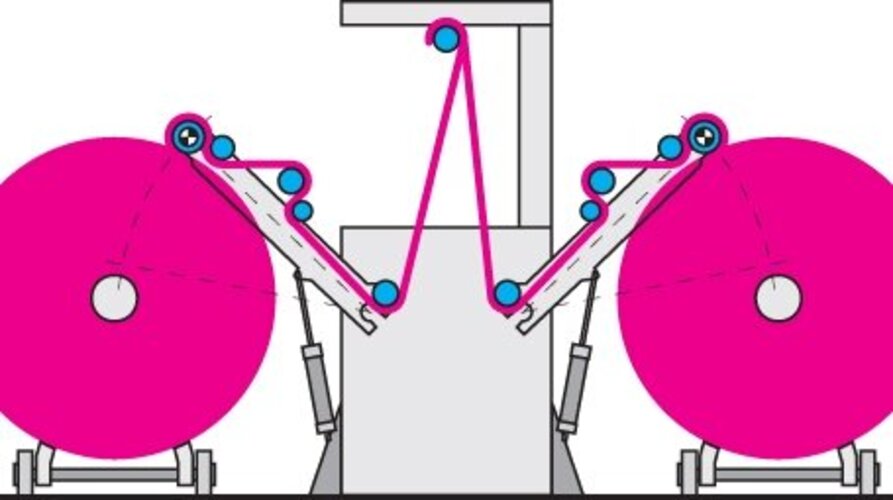

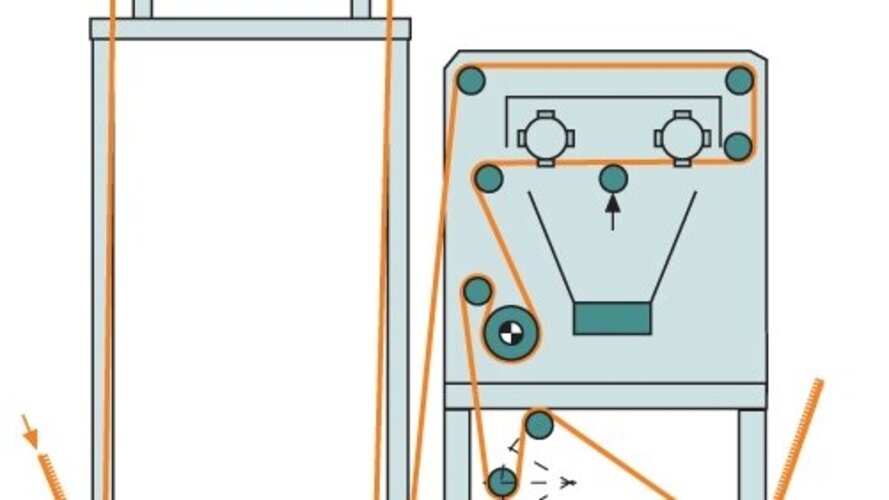

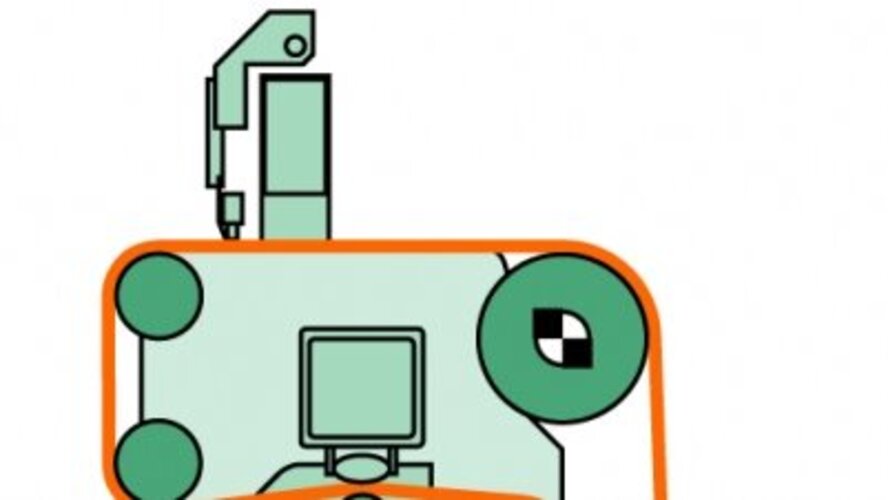

Evac provides you with process capability and reproducibility at low running cost due to the following System Modules: Patented EVAC Slot, EVAC Separators, EVAC Pumping Station, and EVAC System Controls..

Process Capability and Reproducibility at the Lowest Cost

No other vacuum system available today contains all of these design features, which make Evac systems the superior choice in overall performance.

Vacuum Technology – The Principle

Evac systems integrated into open-width textile ranges will improve fabric quality, increase production speed, significantly lower production cost per meter, and lessen the overall environmental impact of textile processes. Following are just a few examples of how vacuum technology can achieve these advantages for the textile producer.

Vacuum technology improves fabric quality by removing lint and dust when dry, and by improving chemical penetration in wet processes. Lint or dust removal can be very advantageous in printing where “stickins” result in second quality fabric. In chemical finishing and pigment “dyeing”, vacuum can pull the chemicals deep inside the fabric, where the end-user appreciates them most. Vacuum technology also prevents the “windowpane” effect, or chemical build-up between yarns.

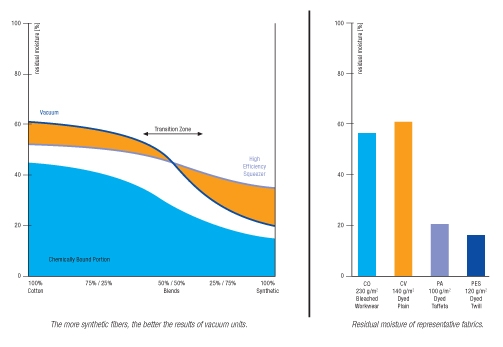

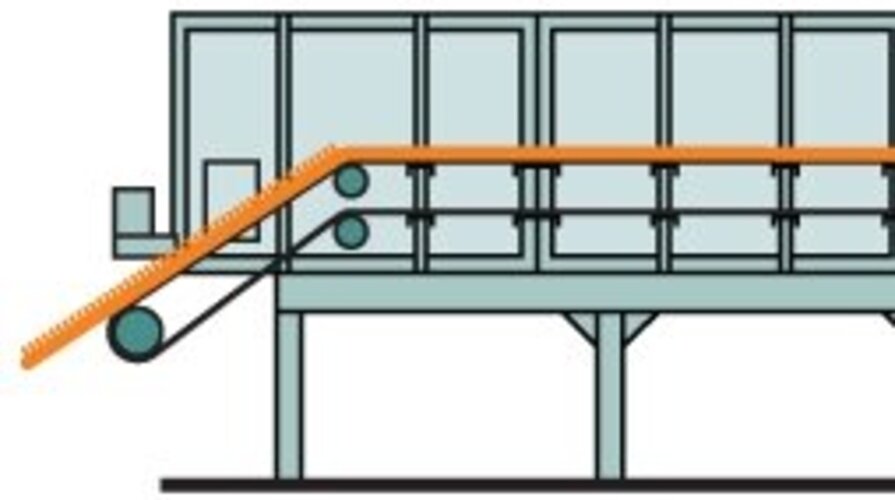

By lowering residual moisture below the level of typical padmangles, vacuum technology allows stenters and other drying devices to dry fabric faster, thus increasing production speed, or lessen the energy consumption.

In washing, vacuum technology separates contaminants from the washing line before they are carried into following washing boxes. The effect: less clean water is needed, which also results in less energy consumption for hot washing purposes. In finishing, vacuum technology removes the chemicals suspended between fabric yarns. The chemicals stay inside the fiber bundles of the yarn, not in between the yarns, and can, easily be recycled. Therefore, fewer grams of chemicals per square meter of fabric are required when using vacuum technology in finishing than when using the padder alone.

In washing, parts of the counterflowing dirty liquor is sent to separate treatment by using the vacuum system. PVA size, bleaching chemicals or unfixed dyestuffs are removed from the washing line before they enter the succeeding wash boxes. Likewise in finishing, by removing chemicals such a fluorocarbons, resins, softeners and even pigments normally left in between fabric yarns, very little chemicals remain to become vaporized and exhausted as emissions out of the stenter’s exhaust outlets.

The operator only selects the vacuum pressure needed and the Evac automatically adjusts pump speeds and airflows to ensure consistent pressure and production results. Pumps as well as seals and separators need only minimal, routine maintenance.

It is not just the quality of our vacuum systems that makes us number one world-wide. It is also the process experience behind the Evac system designs that ensures that the customer receives a vacuum system that is tailored to his specific needs, for as yarn characteristics and fabric constructions vary tremendously, so too do the potential effects of vacuum pressure vary from fabric to fabric. Take advantage of Evacs knowledge in vacuum technology!

EVAC Advantages

- High line-speed increases with synthetics and blends

- Prior to drying cans, stenters or tensionless dryers

- Prior to bleach saturators for high chemical add-on

- Superior process control through even wet pick-up

- Gentle on fabric piles or delicate woven structures

- After Cold Pad Batch desizing or bleaching

- After preparation steamer

- After print washing

- After dye washing

- After stabilization in mercerizing

- Removal and separation of up to 80% of contaminants

- Even application of chemistry through fabric width

- Improved hand due to deep penetration of chemistry into fiber bundles

- No waste of chemicals due to filtering and recycling of chemicals

- Faster stenter speeds due to lower wet pick-up

- Dyestuff and chemical application in one stenter pass

- Excellent wet and dry crock

- Minimal capital investment

- No migration or clip marks

- Prior to printing to reduce second quality prints

- Prior to singing to improve singe

- After shearing or sanding for fabric cleaning

- Reduces lint and dust build-up on downstream rolls, wash boxes, dryers

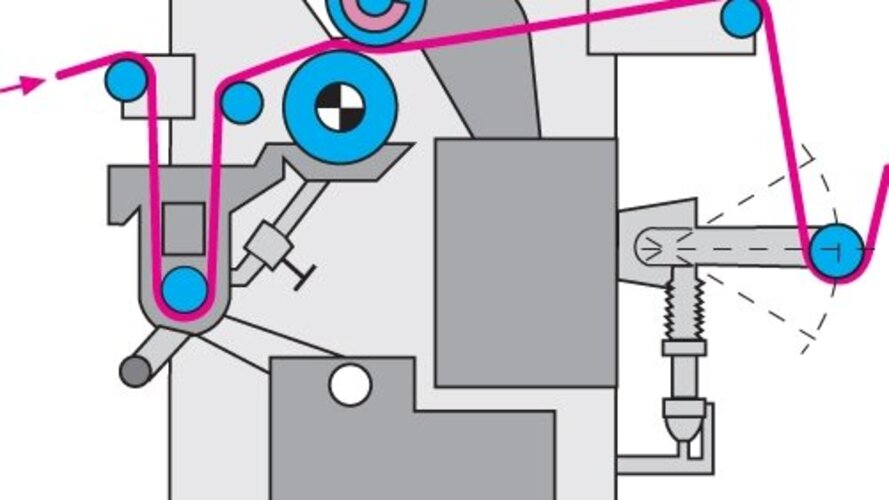

EVAC System Modules

- Inverter-integrated vacuum pressure control

- Minimized electricity consumption

- P.I.D. Loop control

- Automatic cleaning features

- Automatic signals for filter, separator and drain pump maintenance

- Water-cooled pump

- High volumes of air possible

- Long operating life

- Inverter compatible

- Savings in electricity

- Sound enclosure (optional)

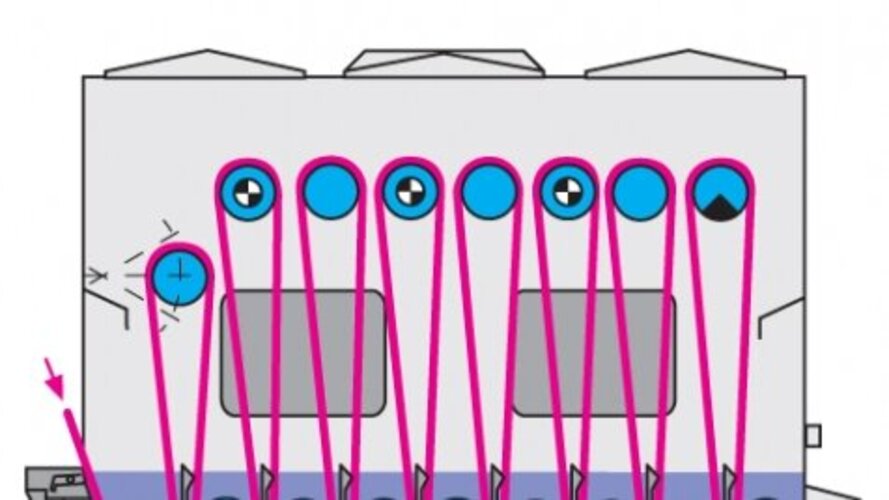

- 95% Efficient, blockage-free design

- No in-line filters

- External filter system

- Filter change possible without stopping system or range

- Automatic signal on control panel for filter change

- Automatic rinsing during lot changes

- Dyestuff and chemical application in one stenter pass

- Excellent wet and dry crock

- Minimal capital investment

- No migration or clip marks

- Minimizes blockages

- Homogenous effects over entire width

- Ideal for pigment dyeing

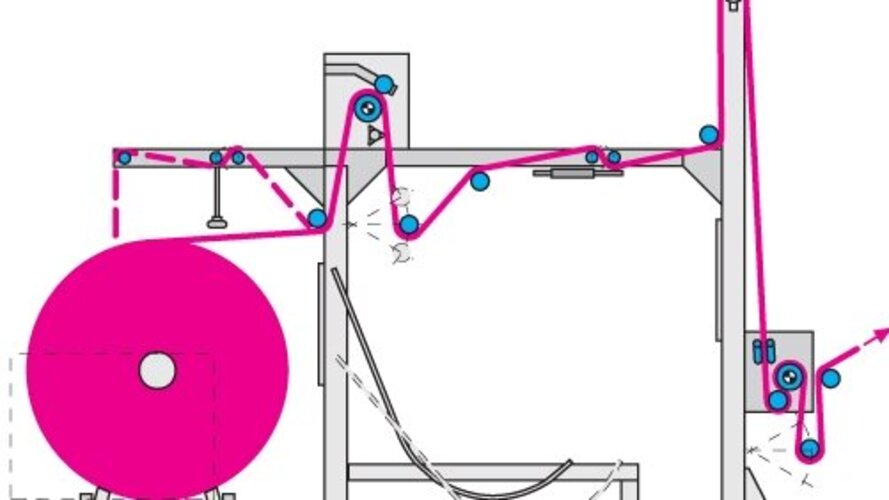

- Low friction UHMW nozzle

- Converging-diverging nozzle orifice for maximum efficiency

- Suitable for high temperatures and chemicals

- Automatic cleaning feature

- Teflon-coating inside and out for ease of maintenance